Isi isi ike Tungsten Carbide oyi na-anwụ anwụ / Isi Carbide Cemented na-anwụ

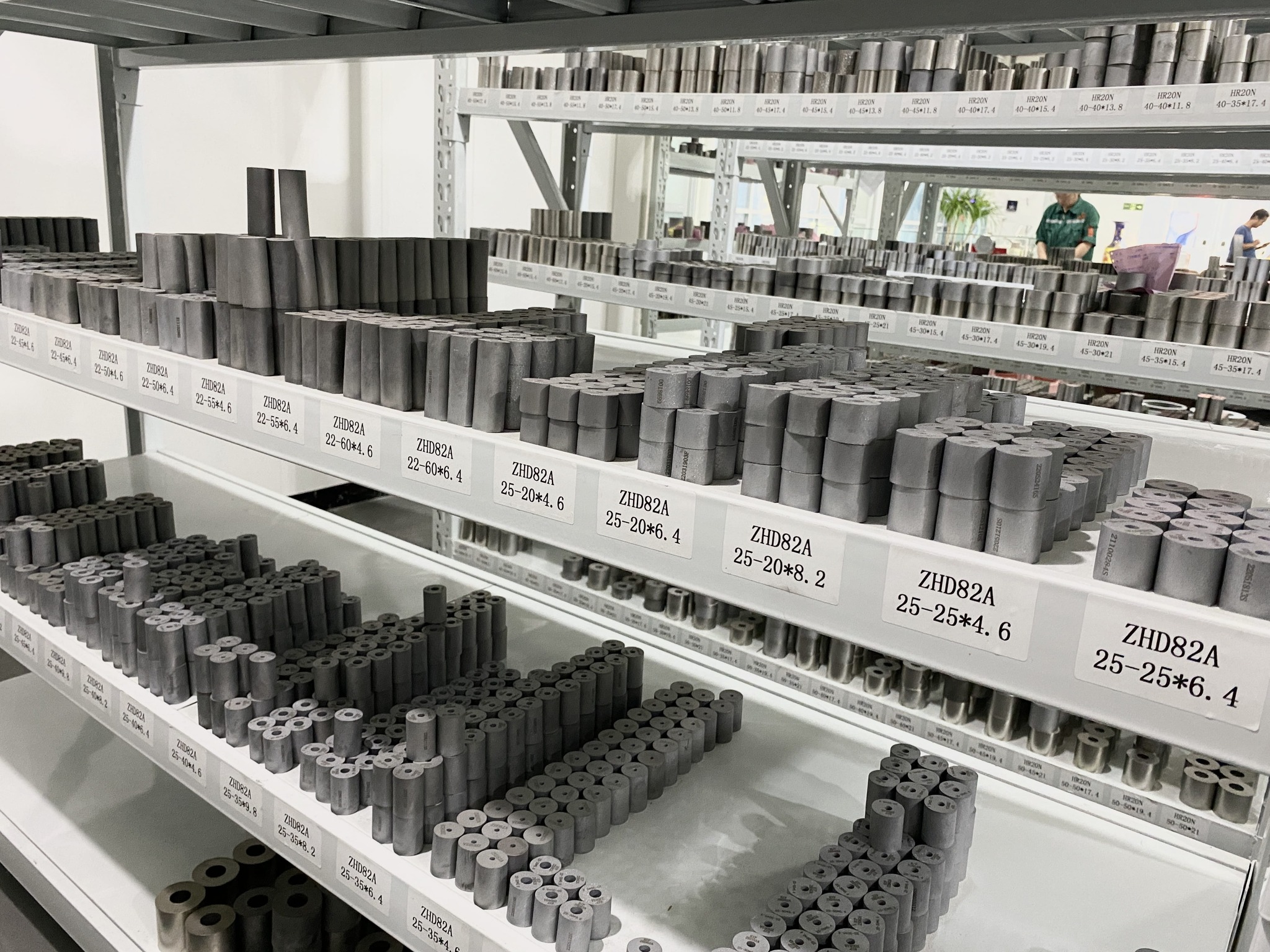

1. Ụlọ ọrụ China ọkachamara na nhazi na mmepụta ihe, asambodo ISO.

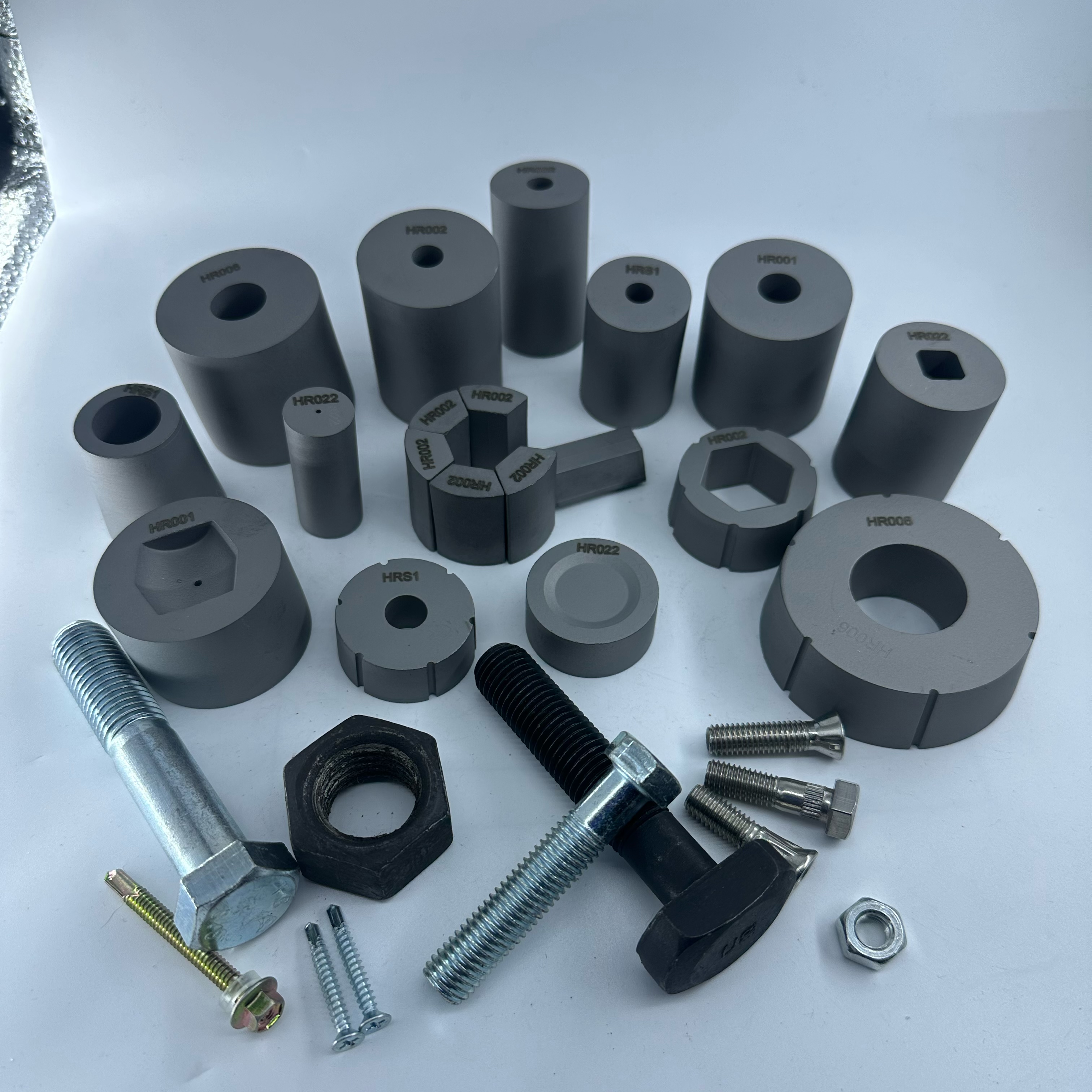

2. Ọtụtụ nha na ụdị dị maka OEM.

3. Mere nke 100% mbụ elu-edu ihe

4. Ndị otu mmepụta ọkachamara, nnyefe ngwa ngwa

5. Free ọkachamara mgbe-ahịa ọrụ na oru nkwado

| ungsten Carbide Cold Forging/heading Dies | ||||

| akara ule | Njupụta | TRS | Isi ike | Arụmọrụ & ngwa akwadoro |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ịme ma ọ bụ stampụ na-anwụ maka ntụ ntụ ígwè na ntụ ntụ na-abụghị metal. |

| YG15 | 14 | ≥3400 | 87.5 | N'ihi na-emepụta ịbịaru anwụ nke ígwè tubes na mkpara n'okpuru High compressibility ruru;ịkụ ọkpọ, stamping, ngwá ọrụ arụrụ arụ n'okpuru nnukwu nrụgide. |

| YG20 | 13.5 | ≥3800 | 85.5 | Maka imepụta stamping na-anwụ maka akụkụ elekere, efere mmiri nke ngwa egwu, ite batrị, bọọlụ obere nha, skru, mkpuchi mkpuchi. |

| YG15C | 14 | ≥4000 | 86.5 | Maka mpempe cone mmanụ, belata ọkara dị nro na nkume siri ike;nkwụsị na ịcha osisi oyi kpọnwụrụ, osisi dị nro na osisi mbụ. |

| YG16C | 13.9 | ≥3500 | 85.5 | Mwepu nguzogide mmetụta na-anwụ. |

| YG18C | 13.7 | ≥3600 | 84.5 | Nkwụsị nkwụsi ike na-anwụ anwụ, ịhịa aka na-ekpo ọkụ na-anwụ anwụ na rollers. |

| YG20C | 13.5 | ≥3800 | 83.5 | Na-anwụ maka ngwa na-eguzogide iyi ma ọ bụ mmetụta. |

| YG22C | 13.3 | ≥4000 | 83 | Ịkpụ akị na-anwụ na nguzogide dị elu na-anwụ anwụ. |

| YG25C | 13.1 | ≥4250 | 82.5 | nkụnye eji isi mee ihe na-enweghị igwe na-anwụ anwụ yana rollers. |

Ngwakọta ihe → Igwe igwe mmiri mmiri → Ngwakọta WC na ike Cobalt → ịpị → HIP Sintering Furnaces → Nchọpụta QC → mbukota

- Usoro mmepụta ọ bụla nwere onye pụrụ iche iji nwalee iji hụ na ịdị mma

- Nwee ndị injinia ọkachamara ka ịlele ogo

- Ngwaahịa niile nọ n'okpuru njikwa sistemụ arụmọrụ siri ike dabere na ISO9001: 2008

1. Nzaghachi n'ime awa 48;

2. Ezi nkwurịta okwu Bekee;

3. Ndụmọdụ ndị ọkachamara na ngwaahịa;

4. Ezi ọzụzụ onye na-ere ahịa mbupụ;

5. Ọkà na tungsten carbide ire;

6. Mgbe ọrụ ahịa gasịrị.

Anyị ga-ebuga uka emepụtara ibu n'ime 30days mgbe ala ugwo, mgbe, Ọ bụrụ na e nwere soecific arịrịọ na nnyefe oge.Anyị nwere ike ịme mgbanwe dịka arịrịọ ndị ahịa si dị, yabụ oge nnyefe dị mkpụmkpụ dị kpamkpam.

Na-emekarị 30% T / T n'ihu, na-edozi 70% megide akwụkwọ B/L.Ọ nwekwara ike gbanwee dịka arịrịọ ndị ahịa si dị.

Anyị na-emepụta ihe dị iche iche na ụdị dị iche iche iji kwekọọ ihe ndị ahịa anyị chọrọ kpọmkwem, ma ha chọrọ ngọngọ ma ọ bụ mpempe akwụkwọ, cylinders, bearings, tips ma ọ bụ ezé.