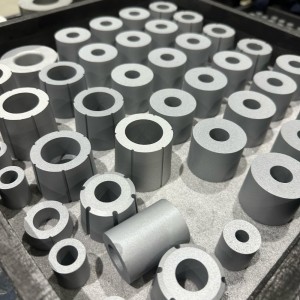

Isi isi ike Tungsten Carbide oyi na-anwụ anwụ / Isi Carbide Cemented na-anwụ

1. Ụlọ ọrụ China ọkachamara na nhazi na mmepụta ihe, asambodo ISO.

2. Ọtụtụ nha na ụdị dị maka OEM.

3. Mere nke 100% mbụ elu-edu ihe

4. Ndị otu mmepụta ọkachamara, nnyefe ngwa ngwa

5. Free ọkachamara mgbe-ahịa ọrụ na oru nkwado

1.Cemented carbide pellets na-eji ọtụtụ ebe oyi heading anwụ na ọkpọ anwụ

maka imepụta mkpụrụ, bolts na ọtụtụ ngwaahịa ndị ọzọ.

2.The ọkwa GT55 / YG25C bụ ihe kasị n'ọtụtụ ebe na-eji ihe na-eme ka carbide pellets.

Ọ nwere ihe ndị mara mma nke na-eduga n'ịrụ ọrụ dị mma na ogologo oge ọrụ.

3.Except maka ọkọlọtọ nha, nonstandard nha nke carbide pellets

nwekwara ike na-emepụta dị ka ndị ahịa chọrọ.

4.All carbide pellets nyochaa nke ọma na ultrasonic flaw detector

iji zere ndị nwere oghere ma ọ bụ mgbawa na-ahapụ ụlọ ọrụ mmepụta ihe.

| Tungsten Carbide Cold Forging/heading anwụọ | ||||

| akara ule | Njupụta | TRS | Isi ike | Arụmọrụ & ngwa akwadoro |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ịme ma ọ bụ stampụ na-anwụ maka ntụ ntụ ígwè na ntụ ntụ na-abụghị metal. |

| YG15 | 14 | ≥3400 | 87.5 | N'ihi na-emepụta ịbịaru anwụ nke ígwè tubes na mkpara n'okpuru High compressibility ruru;ịkụ ọkpọ, stamping, ngwá ọrụ arụrụ arụ n'okpuru nnukwu nrụgide. |

| YG20 | 13.5 | ≥3800 | 85.5 | Maka imepụta stamping na-anwụ maka akụkụ elekere, efere mmiri nke ngwa egwu, ite batrị, bọọlụ obere nha, skru, mkpuchi mkpuchi. |

| YG15C | 14 | ≥4000 | 86.5 | Maka mpempe cone mmanụ, belata ọkara dị nro na nkume siri ike;nkwụsị na ịcha osisi oyi kpọnwụrụ, osisi dị nro na osisi mbụ. |

| YG16C | 13.9 | ≥3500 | 85.5 | Mwepu nguzogide mmetụta na-anwụ. |

| YG18C | 13.7 | ≥3600 | 84.5 | Nkwụsị nkwụsi ike na-anwụ anwụ, ịhịa aka na-ekpo ọkụ na-anwụ anwụ na rollers. |

| YG20C | 13.5 | ≥3800 | 83.5 | Na-anwụ maka ngwa na-eguzogide iyi ma ọ bụ mmetụta. |

| YG22C | 13.3 | ≥4000 | 83 | Ịkpụ akị na-anwụ na nguzogide dị elu na-anwụ anwụ. |

| YG25C | 13.1 | ≥4250 | 82.5 | nkụnye eji isi mee ihe na-enweghị igwe na-anwụ anwụ yana rollers. |

Ngwakọta ihe → Igwe igwe mmiri mmiri → Ngwakọta WC na ike Cobalt → ịpị → HIP Sintering Furnaces → Nchọpụta QC → mbukota

Tungsten Carbide Cold Forging anwụ

Tupu mmepụta uka, anyị kwesịrị ime ule ịpị na sintering , na anyị na-elele anya na nha, njupụta na ike nke samples na micrometer, Metallurgical microscope, densitometer wdg iji hụ na ihe ndị a chọrọ nke eserese nwere ike izute tupu ogbe. mmepụta;A ga-enyocharịrị ngwaahịa niile site na QC anyị.

A na-eji pellet carbide simented eme ihe n'ọtụtụ ebe n'isi oyi na-anwụ na ịkụ ọkpọ

maka ịkpụ mkpụrụ osisi, okpu screw, bolts, cans na ọtụtụ ngwaahịa ndị ọzọ.

1. Ezi nguzogide corrosion.

2. Elu nkenke.

3. Ra0.2 elu roughness.

4. Emere site na 100% na-amaghị nwoke akụrụngwa.

5. Emepụtara aga site na usoro na nyocha ikpeazụ.

6. Stable na-aga n'ihu mmepụta ike.

1. Nzaghachi n'ime awa 48;

2. Ezi nkwurịta okwu Bekee;

3. Ndụmọdụ ndị ọkachamara na ngwaahịa;

4. Ezi ọzụzụ onye na-ere ahịa mbupụ;

5. Ọkà na tungsten carbide ire;

6. Mgbe ọrụ ahịa gasịrị.

Anyị ga-ebuga uka emepụtara ibu n'ime 30days mgbe ala ugwo, mgbe, Ọ bụrụ na e nwere soecific arịrịọ na nnyefe oge.Anyị nwere ike ịme mgbanwe dịka arịrịọ ndị ahịa si dị, yabụ oge nnyefe dị mkpụmkpụ dị kpamkpam.

Na-emekarị 30% T / T n'ọdịnihu, itule 70% TT tupu nnyefe.Ọ nwekwara ike gbanwee dịka arịrịọ ndị ahịa si dị.

Anyị na-emepụta ihe dị iche iche na ụdị dị iche iche iji kwekọọ ihe ndị ahịa anyị chọrọ kpọmkwem, ma ha chọrọ ngọngọ ma ọ bụ mpempe akwụkwọ, cylinders, bearings, tips ma ọ bụ ezé.