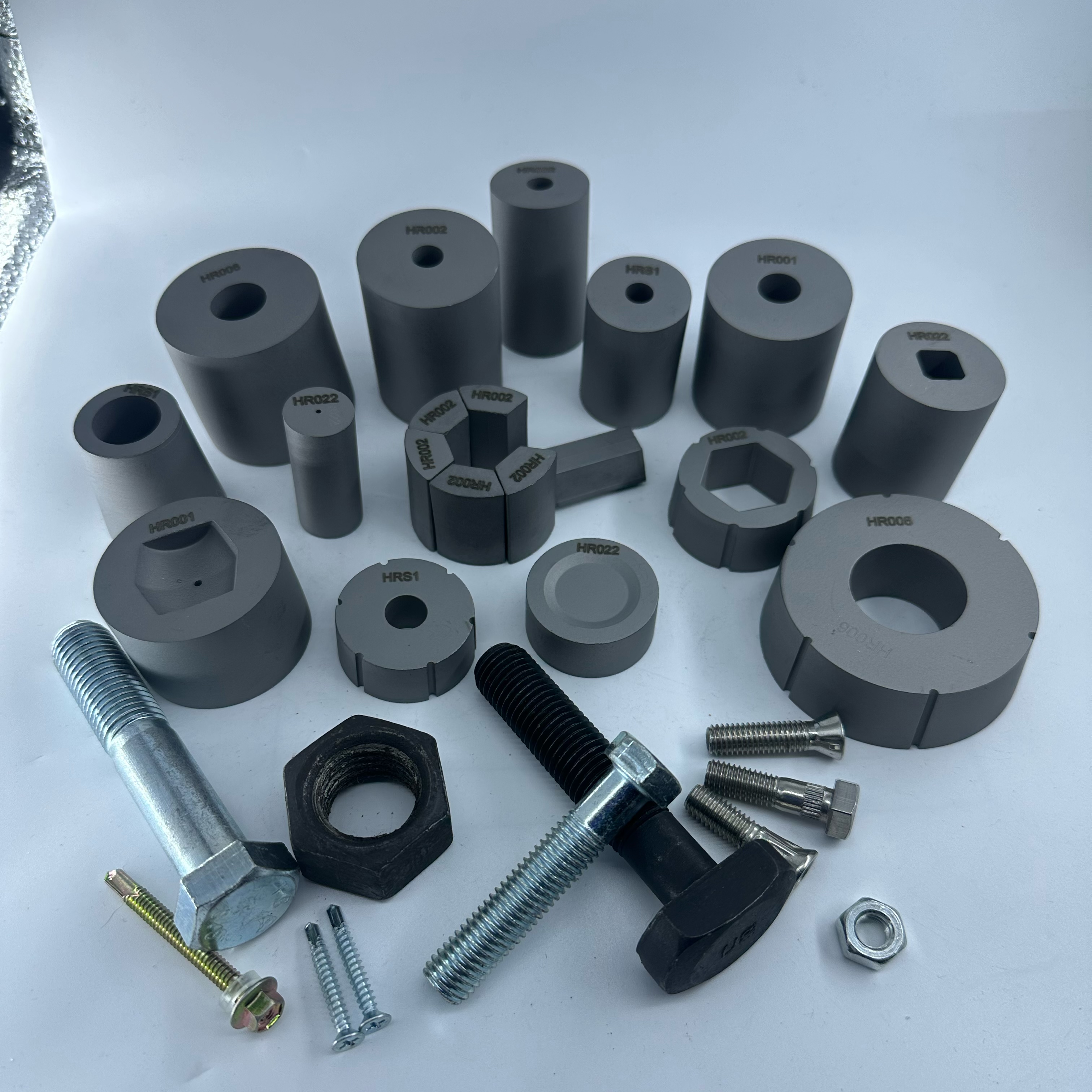

100% Virgin Tungsten Carbide Fastener Industry Jiri Tungsten Carbide Cold Forging Die

Arụmọrụ Ọkwa:

| Tungsten Carbide Cold Forging/heading anwụọ | |||||

| akara ule | Njupụta | TRS | Isi ike | Arụmọrụ & ngwa akwadoro | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Ịme ma ọ bụ stampụ na-anwụ maka ntụ ntụ ígwè na ntụ ntụ na-abụghị metal. | |

| YG15 | 14 | ≥3400 | 87.5 | N'ihi na-emepụta ịbịaru anwụ nke ígwè tubes na mkpara n'okpuru High compressibility ruru;ịkụ ọkpọ, stamping, ngwá ọrụ arụrụ arụ n'okpuru nnukwu nrụgide. | |

| YG20 | 13.5 | ≥3800 | 85.5 | Maka imepụta stamping na-anwụ maka akụkụ elekere, efere mmiri nke ngwa egwu, ite batrị, bọọlụ obere nha, skru, mkpuchi mkpuchi. | |

| YG15C | 14 | ≥4000 | 86.5 | N'ihi na mmanụ cone akuakuzinwo ibe n'ibe, bee ọkara rọrọ na nkume siri ike; Debarking na igbutu nke oyi kpọnwụrụ osisi, nro osisi na mbụ osisi. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Mwepu nguzogide mmetụta na-anwụ. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Nkwụsị nkwụsi ike na-anwụ anwụ, ịhịa aka na-ekpo ọkụ na-anwụ anwụ na rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Na-anwụ maka ngwa na-eguzogide iyi ma ọ bụ mmetụta. | |

| YG22C | 13.3 | ≥4000 | 83 | Ịkpụ akị na-anwụ na nguzogide dị elu na-anwụ anwụ. | |

| YG25C | 13.1 | ≥4250 | 82.5 | nkụnye eji isi mee ihe na-enweghị igwe na-anwụ anwụ yana rollers. | |

Isi ike dị elu na nkwụghachi nke iyi akwa

Hengrui Cemented Carbide siri ike na nguzogide iyi ka mma, anaghị eyi ya nke ukwuu, n'ihi iji ogologo oge.

Adịghị emebi elu akụkụ nke Machined

Ngwaahịa ndị ahụ dị nro ma dị nro, yana ọrụ nke Nanometer Diamond Coatings, na-enye ngwaahịa ndị ahụ ihe njedebe dị mma na njedebe dị ala, agaghị emebi elu nke akụkụ ahụ.

Nguzogide corrosion

Ezigbo Nguzogide Oxidation, n'ozuzu, ọ na-eguzogide oke ikuku, acid, na Alkali corrosion, adịghị mfe iji oxidize, ma nwee ike ịnọgide na-eguzosi ike n'ezi ihe nke ngwaahịa.

Ngwa dị ukwuu

Ejiri ya nke ọma n'ụlọ ọrụ dị iche iche maka ịse, ịkpụzi na ịkpụzi anwụ.dị ka igwe anaghị agba nchara, tebụl, arịa ọla, ngwa ngwa ngwa wdg.

| Aha ngwaahịa | Tunsten Carbide oyi isi anwụ anwụ |

| Ihe onwunwe | cemented carbide |

| Nha | φ20 * φ5.5 * 41 ma ọ bụ nke emebere |

| Nkwenye nha nha | Nnwere onwe n'efu ma ọ bụ dị ka arịrịọ ndị ahịa |

| Agba | Agba ntụ |

| Kwadoro ọkwa | YG20C YG22C YG25C wdg |

| Nha ọka | Mkpụrụ ọka |

| Ngwa | Maka ụlọ ọrụ Fastener |

| Usoro ọgwụgwọ | N'ala mgbe agbachara ájá ma ọ bụ ala dị ọcha ma na-egbu maramara wdg |

| Njirimara ngwaahịa | Ogologo ndụ, mmetụta dị mma na-eguzogide |

| Asambodo | ISO9001 |

Ngwakọta ihe → Igwe igwe mmiri mmiri → Ngwakọta WC na ike Cobalt → ịpị → HIP Sintering Furnaces → Nchọpụta QC → mbukota

Tupu mmepụta uka, anyị kwesịrị ime ule ịpị na sintering , na anyị na-elele anya na nha, njupụta na ike nke samples na micrometer, Metallurgical microscope, densitometer wdg iji hụ na ihe ndị a chọrọ nke eserese nwere ike izute tupu ogbe. mmepụta;A ga-enyocharịrị ngwaahịa niile site na QC anyị.

1. Anyị ga-agbalị ike anyị ịza anyị ahịa' arịrịọ n'ime 24hours.

2. Anyị ga-ejigide ndị ahịa anyị na nkwukọrịta dị irè ma dị irè.

3. Anyị na-enye njikwa ogo ọkwa mbụ na ọrụ ire ere.

Anyị ga-ebuga uka emepụtara ibu n'ime 30days mgbe ala ugwo, mgbe, Ọ bụrụ na e nwere soecific arịrịọ na nnyefe oge.Anyị nwere ike ịme mgbanwe dịka arịrịọ ndị ahịa si dị, yabụ oge nnyefe dị mkpụmkpụ dị kpamkpam.

Na-emekarị 30% T / T n'ọdịnihu, itule 70% T / T tupu nnyefe.Ọ nwekwara ike gbanwee dịka arịrịọ ndị ahịa si dị.

Anyị na-emepụta ihe dị iche iche na ụdị dị iche iche iji kwekọọ ihe ndị ahịa anyị chọrọ kpọmkwem, ma ha chọrọ ngọngọ ma ọ bụ mpempe akwụkwọ, cylinders, bearings, tips ma ọ bụ ezé.