Dị ka aha carbide ezé ụlọ ọrụ, ọtụtụ n'ime ndị na-eji ya amaghị otú e si emepụta carbide na ihe dị iche na usoro mmepụta ya, n'eziokwu, mmepụta nke carbide metụtara iji gburugburu ebe obibi.Dịka ọmụmaatụ, carbide maka igwu ala, carbide maka igwu nkume, ckpebisie ikengwaọrụ ntụgharị, wdg niile dabere na ojiji gburugburu ebe obibi.E nwekwara ihe atụ carbide na-eguzogide corrosion na ndị ọzọ.

Kedu ka esi emepụta Carbide Cemented?Gịnị bụ usoro mmepụta ya?

Usoro mmepụta nke carbide cimented bụ n'ozuzu dị ka ndị a: ihe mgbagwoju anya metal siri ike (tungsten carbide, tantalum carbide, wdg), metal bonding (cobalt ntụ ntụ ma ọ bụ nickel ntụ ntụ) na obere ego nke mgbakwunye (stearic acid ma ọ bụ esomin) na-agwakọta na ala na hexane egweri ọkara, na slurry nke paraffin wax na-agbakwunyere, mgbe ahụ na-ekpo ọkụ akpọnwụ (ma ọ bụ fesa akpọnwụ), sieved, granulated, na-mere ka ọ bụrụ ngwakọta;A na-amata ihe a na-agwakọta ma bụrụ onye ruru eru, na mgbe ọ gachara, a na-achọpụta ihe a na-ejikọta ya na nke ruru eru, wee pịa ya ka ọ mee ka ọ bụrụ ihe dị elu;A na-agbaji billet ahụ etinyere site na ime ihe na-adịghị mma ma ọ bụ nrụgide dị ala imecemented carbide.

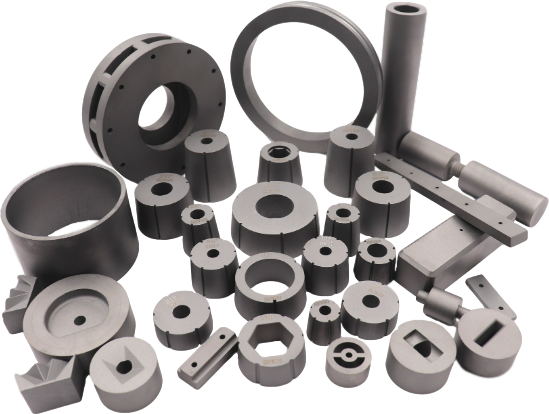

Ụkpụrụ ime ihe

A na-eme usoro ikpo ọkụ na-ekpo ọkụ site na ikpo ọkụ n'okpuru ọnọdụ ikuku, nke na-eme ka ikpochapụ ihe ndị na-adịghị ọcha, na-eme ka ịdị ọcha nke ikuku ikuku dị ọcha, na-eme ka wettability nke njikọ njikọ na ịkwalite mmeghachi omume.A na-ekpo ọkụ billet a na-agbanye n'ime ikuku na-ekpo ọkụ, na ka okpomọkụ na-ebili ma rute okpomọkụ nke evaporation, ọ na-agbanarị na billet a na-agbanye ma na-ejide ya ruo oge zuru oke na nrụgide nke paraffin na-erughị okpomọkụ ahụ, na paraffin. a na-esi n'obere mpempe akwụkwọ a pịara apụta wee gbakee, a na-asachapụkwa billet ahụ a pịara ahụ.Ka okpomọkụ na-abawanye n'ihu, a na-ekpochapụ billet ma na-eme ka ọ dị ọcha, na-esikwa ike nke usoro siri ike.Na usoro siri ike na-agba ọsọ, atom (ma ọ bụ molecules) nke ihe ọ bụla na-eme n'ime anụ ahụ na-agbasa, na-amụba akụkụ nke kọntaktị n'elu, anya dị n'etiti irighiri ihe na-ebelata, anụ ahụ na-ebelata ma na-esiwanye ike.Mgbe ọnọdụ okpomọkụ dị nso n'ebe mgbaze nke akụkụ ahụ jikọtara, usoro njikọ na-amalite na-asọba plastik, na mgbe okpomọkụ nke mmiri mmiri na-erute, anụ ahụ na-emepụta ihe na-emepụta mmiri mmiri na mmiri mmiri na-eme.

Na mmiri mmiri na-adọ sintering usoro, a mmiri mmiri na-adọ oyi akwa na-egosi na carbide elu, nacarbideirighiri irighiri agbari na agbụ nke njikọ site mgbasa na-etolite eutectic, na carbide ahụ recrystallize na-eto eto na size site na mmiri mmiri na-adọ, nke mere na n'akụkụ carbide irighiri nwere njikọ chiri anya, na sintered ahu shrinks n'ihu na densifies ngwa ngwa.Ahụ ahụ e mechiri emechi na-agbadakwa ma na-agbaze ngwa ngwa.A na-ejide ya na okpomọkụ dị elu karịa okpomọkụ na-ekpo ọkụ nke mmiri mmiri ruo oge ụfọdụ iji mee ka usoro nhazi ahụ gaa n'ihu n'ụzọ zuru ezu, wee mee ka ọ dị jụụ.

N'ime usoro ihe ọkụkụ ahụ dum, a na-eme ka ahụ ahụ dị nro na nso nso na-abụghị porosity, na-emepụta usoro nke physicochemical mmetụta na nhazi nhazi nhazi, na-eme ka e guzobe nnukwu carbide cemented nwere ụfọdụ ihe mejupụtara kemịkalụ, anụ ahụ na akụrụngwa, na. nhazi nhazi.

Oge nzipu: Jun-29-2023