Ọ bụ ezie na ma tungsten alloy nacemented carbidebụ ụdị alloy ngwaahịa nke mgbanwe metal tungsten, ma nwere ike ji mee ihe na aerospace na ụgbọ elu navigation na ndị ọzọ ubi, ma n'ihi na ihe dị iche nke kwukwara ọcha, mejupụtara ruru na mmepụta usoro, arụmọrụ na ojiji nke ha abụọ nwekwara nnukwu. iche.

I. Nkọwa

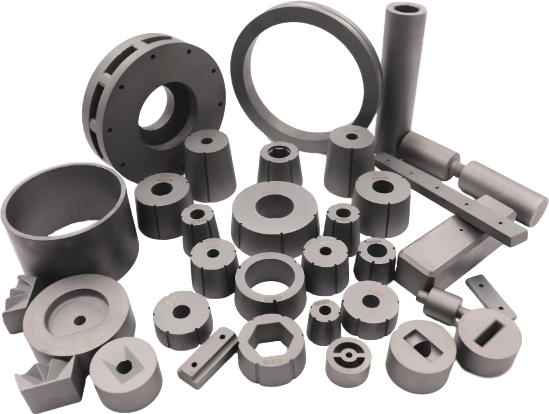

Tungsten alloy, nke a makwaara dị ka ihe ndọda dị elu, bụ alloy nwere tungsten ntụ ntụ dị ka isi akụrụngwa na nickel, ígwè, ọla kọpa na ihe ndị ọzọ dị ka ihe inyeaka.Ọdịnaya tungsten na-adịkarị n'etiti 85% na 99%.

Carbide ciment, nke a makwaara dị ka tungsten ígwè, ya bụ, bụ alloy na refractory metal carbide dị ka tungsten carbide dị ka isi ihe na cobalt, nickel, molybdenum na ihe ndị ọzọ dị ka ihe nkedo.Ọdịnaya njide na-adịkarị n'etiti 10% na 20%.

Nke abụọ, arụmọrụ

Igwe ndọda dị elu dị elu nwere ebe mgbaze dị elu, njupụta, ike na ike siri ike, plasticity ka mma, nguzogide okpomọkụ, nguzogide corrosion,, nguzogide mmetụta, nguzogide oxidation na mmetụta mkpuchi.

Tungsten ígwè nwekwara ihe ndị yiri ya na tungsten alloys, n'agbanyeghị na ya thermal ike ike na iyi nguzogide uru bụ nnọọ ihe doro anya, tumadi na eziokwu na ọ na-anọgide na isi agbanweghị na 500°C ma ka nwere nnukwu ike na 1000°C.Otú ọ dị, brittleness ya dị oke elu, n'ihi ya, ọ na-arụ ọrụ nhazi.

Nke atọ, usoro mmepụta

Nzọụkwụ nkwadebe nke tungsten alloy: 1) Nkwadebe ihe: ogige tungsten dị ka ammonium tungstate, ihe enyemaka dị ka nickel, ígwè, ọla kọpa na ihe ndị ọzọ ma ọ bụ ogige;2) ntụ ntụ ime: e nwere ịgba ihicha usoro na n'ibu alloying usoro;3) na-akpụ: mgbe agwakọta tungsten ntụ ntụ na onye na-emepụta ihe, a na-agbanye extrusion n'ime igwe na-emepụta, mgbe ahụ enwere ike ịkwadebe akụkụ ndị nwere mgbagwoju anya;4) sintering: mgbe sintering ọgwụgwọ, nzukọ nke alloy bụ ihe edo na keukwu arụmọrụ elu n'ozuzu arụmọrụ.

Nzọụkwụ maka nkwadebe nke cemented carbide: 1) Wepụ elu adịghị ọcha nketungsten carbideahụ na ọka cobalt;2) Ghichaa ihe ndị dị n'elu ma gwakọta ha na igwekota, wee gwerie ha iji nweta ntụ ntụ ntụ;3) Extrude na alloy ntụ ntụ n'ime extrusion anwụ iji nweta cemented carbide precursors, mgbe ahụ, mix ha mmiri mmiri na tinye ihe nkedo na-eme ka metal ntụ ntụ slurry;4) Mee slurry ka ọ bụrụ ntụ ntụ site na ịgba granulator, wee sinarị na ọgwụgwọ okpomọkụ.wee sintered na okpomọkụ mesoo.

Oge nzipu: Jun-02-2023