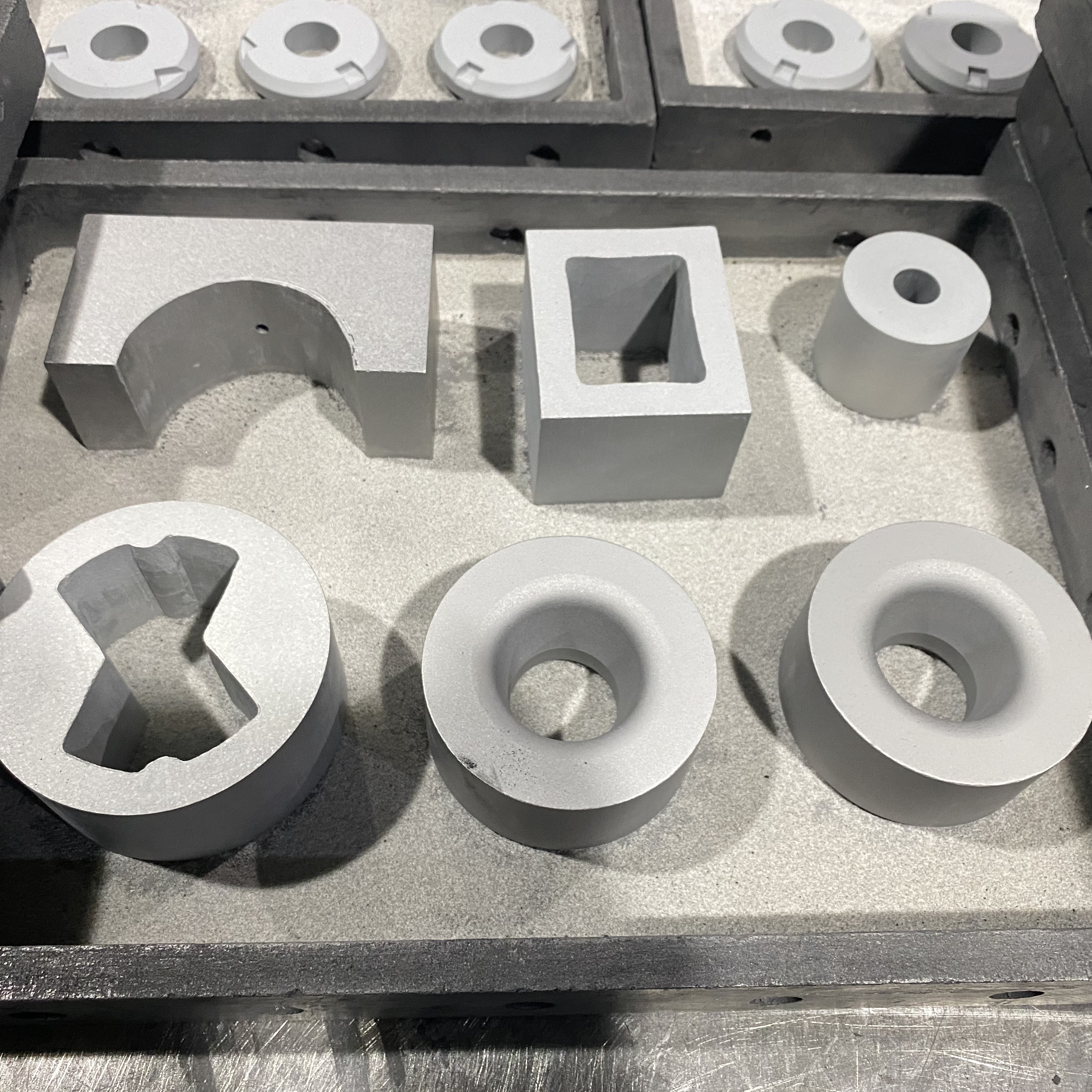

The sintering nkecemented carbidebụ mmiri mmiri frasi sintering, ntụgharị re-njikọ na-adọ bụ na mmiri mmiri frasi.A na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na 1350 ° C-1600 Celsius n'ime ọkụ ọkụ.Mbelata ahịrị ahịrị nke billet etinyere n'oge sintering bụ ihe dịka 18% na mbelata olu dị gburugburu 50%.The kpọmkwem uru nke shrinkage dabere na urughuru size nke ntụ ntụ na mejupụtara nke alloy.

Ịgba nkecemented carbidebụ usoro physicochemical dị mgbagwoju anya, nke na-agụnye mwepụ nke plasticizer, degassing, siri ike na-agba ọsọ na-agba ọsọ, mmiri mmiri na-agba agba, alloying, densification, dissolution precipitation na usoro ndị ọzọ.A na-agbanye billet ahụ etinyere n'okpuru ọnọdụ ụfọdụ iji mepụta ngwaahịa nwere ụfọdụ ihe mejupụtara kemịkalụ, nhazi, njirimara na ọdịdị na nha.Usoro usoro ndị a na-adịgasị iche nke ukwuu dabere na unit sintering.

Cimemented carbide vacuum sintering bụ usoro nke a na-eme ihe na-erughị 1 atm (1 atm = 101325 Pa).Sintering n'okpuru ọnọdụ agụụ na-ebelata nke ukwuu nkwụsị nke densification site na adsorbed gas na ntụ ntụ na gas na pores mechiri emechi, nke na-eme ka usoro mgbasa ozi na densification, na-ezere mmeghachi omume n'etiti ígwè na ụfọdụ ihe na ikuku n'oge okpomọkụ. Sintering usoro, na nwere ike budata mma wettability nke mmiri viscous frasi na ike agba, ma agụụ sintering kwesịrị ịṅa ntị iji gbochie evaporation ọnwụ nke cobalt.Enwere ike kewaa oghere oghere ụzọ anọ, ya bụ ogbo mwepụ nke plasticizer, ogbo tupu oge eruo, ọkwa ikpo ọkụ dị elu na ọkwa jụrụ oyi.

Ogbo mwepụ nke plasticizer na-amalite site na ọnụ ụlọ okpomọkụ wee rute ihe dịka 200 Celsius.The gas adsorbed n'elu nke ntụ ntụ irighiri ke billet kewapụrụ n'elu nke ahụ n'okpuru omume nke okpomọkụ na-esi na billet na-aga n'ihu.A na-ekpo ọkụ plasticizer na billet wee gbapụ na billet.Ịnọgide na-enwe ọkwa dị elu nke agụụ na-eme ka ntọhapụ na mgbapụ nke gas.Ụdị dị iche iche nke plasticizers nwere ihe dị iche iche mgbe a na-etinye ya n'ọkụ, ya mere ekwesịrị ịmepụta usoro iwepụ plasticizer dịka ọnọdụ dị iche iche si dị.

Ekwesịrị ikpebi usoro mwepụ plastik dịka ọnọdụ akọwapụtara nke ule ahụ si dị.N'ozuzu plasticizer gasification okpomọkụ dị n'okpuru 550 ℃.

Pre-sintering ogbo na-ezo aka elu okpomọkụ sintering tupu tupu sintering, nke mere na chemical oxygen na ntụ ntụ ahụ na carbon Mbelata mmeghachi omume n'ịwa carbon monoxide gas na-ahapụ ndị pịa billet, ma ọ bụrụ na nke a gas enweghị ike ewepu mgbe mmiri mmiri na-apụta, ga-aghọ ihe mechiri emechi pore fọdụrụnụ na alloy, ọbụna ma ọ bụrụ na pressurized sintering, o siri ike ikpochapụ.N'aka nke ọzọ, ọnụnọ nke oxidation ga-emetụta nke ukwuu wettability nke mmiri mmiri na-agbasi ike na-emesị emetụta usoro densification nke cemented carbide.Tupu usoro mmiri mmiri apụta, a ga-ekpochasị ya nke ọma na enwere ike iji oghere kachasị elu mee ihe.

Okpomọkụ na-ekpo ọkụ na oge nkwụsịtụ bụ usoro usoro dị mkpa maka densification nke billet, ịmepụta usoro ihe na-emekọ ihe na inweta ihe ndị a chọrọ.Okpomọkụ na-ekpo ọkụ na oge nkwụsịtụ na-adabere na ngwakọta alloy, nha ntụ ntụ, ike na-egweri nke ngwakọta na ihe ndị ọzọ, ma na-achịkwa ya site na nhazi nke ihe niile.

Oge nzipu: Jun-08-2023